The Hidden Costs Of Cutting Tools

For precision machining, what properties should tool materials have?

If you are in the business of precision machining, you know that the quality of your tools is critical. The process of cutting metal is carried out under high cutting temperature and severe friction conditions. Therefore, in the process of machining precision parts, the length of tool life and the level of cutting efficiency, Depending on the tool material, the tool material determines the fundamental factor of the cutting performance of the tool, and has a great impact on the efficiency, quality of processing, cost of processing and tool durability In order to achieve the desired results, you need materials that have the right properties. Here are some things to consider when choosing tool VNMG Insert materials.

High hardness: The hardness of the tool material needs to be higher than that of the workpiece material to cut metal, and the hardness should reach above 60HRC at room temperature.

High wears resistance: Wears resistance is expressed as the ability of the tool material to resist wear. Usually, the higher the hardness, the better the wears resistance of the material.

Sufficient strength and toughness: The tool material needs to have sufficient strength and toughness to ensure that the tool can withstand sufficient total cutting force, shock and vibration during the normal cutting process of precision machining to prevent chipping or brittle fracture of the tool.

High heat resistance: Heat resistance, also known as hard heat, refers to the ability of tool PVD Coated Insert materials to maintain cutting performance at high temperatures, and it is the main indicator to measure the performance of tool materials.

Good Processability: In order to facilitate the production of knives, the knives are required to have good machinability and heat treatment process. Machinability mainly refers to cutting performance and welding performance. Heat Treatment refers to small heat treatment deformation, thin decarburization layer and good hardenability.

The process performance of the precision machining tool material also has a significant influence on the quality of the tool itself. Therefore, cutting material of the tool must meet the above five requirements.

---------------------------------------------------------------------------------------------------------

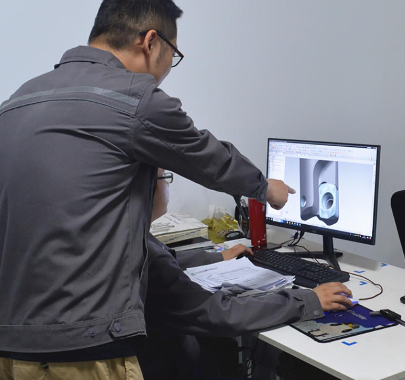

ENS cutting tools Co.,LTD is a professional manufacturer engaged in research, development, production and sale of CNC cutting tools. For example lathe inserts and holders, boring holders, milling inserts and holders, carbide end mills and drills, tool holders.

ENS have automated production lines, the rich experienced design and production team.In recent years, ENS cutting tools have introduced a series of advanced equipment and new technique. In addition we are selling well in most cities and provinces around China. Our produces are also exported to many other countries, such as Germany, UK, Canada, Poland, Switzerland, Korea and so on.

Our goal is to establish longer cooperation relationship with our clients to have a win-win situation.Generally speaking, comparing to some famous Japanese brand, our Nicecutt products have 20% longer tool life, but half price. You could see the case studies in the CASE STUDY tab. Always welcome your consultation.

The Cemented Carbide Blog: http://drillbits.unblog.fr/

برچسب ها : Carbide Turning Inserts,